14 – 16 November 2023, Bremen, Germany

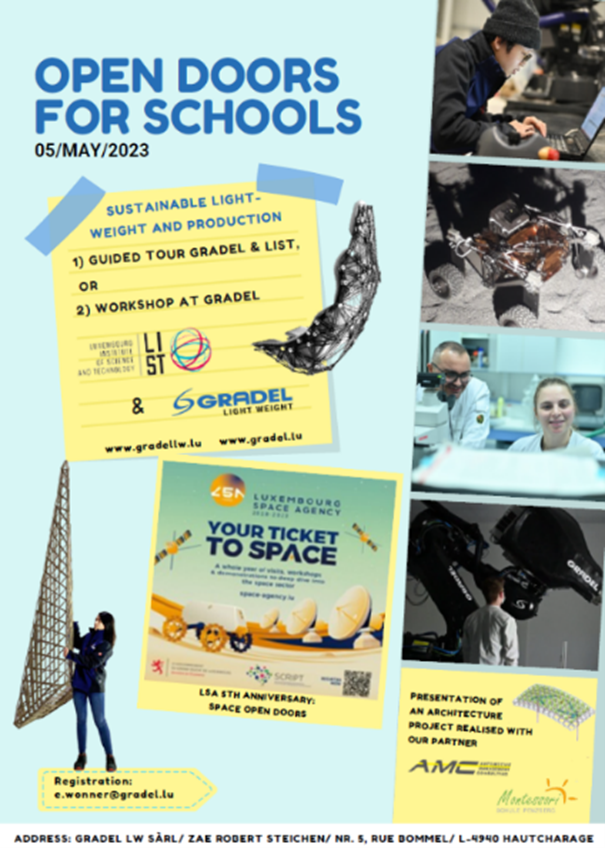

Exciting news in the world of space technology! We are thrilled to announce that GRADEL will be gracing the Luxembourguish booth at Space Tech Bremen 2023 once again. Get ready for an immersive experience filled with groundbreaking updates on space activities and lightweight structures.

As a pioneer in the field, GRADEL has consistently pushed boundaries, revolutionizing the way we perceive space exploration. With our cutting-edge technology and unwavering commitment to excellence, we are helping shape the future of the aerospace industry.

At Space Tech Bremen 2023, GRADEL is set to unveil an array of exciting news and developments. Our booth promises an immersive journey into the advancements made in the realm of space activities, highlighting our relentless pursuit of innovation. From groundbreaking research projects to visionary concepts, we are eager to share our latest achievements with you.

Moreover, our focus on lightweight structures has enabled us to redefine the limits of aerospace engineering. With our expertise in designing and manufacturing lightweight components, GRADEL has successfully surpassed traditional barriers, enabling more efficient and sustainable aerospace systems. Come explore our lightweight solutions that are shaping the industry’s future.

Whether you are a space enthusiast, industry professional, or simply curious about the advancements in space technology, joining us at Space Tech Bremen 2023 will be an opportunity like no other. Connect with GRADEL’s experts, engage in insightful discussions, and witness firsthand the technologies shaping the future of space exploration.

Follow @GRADEL on LinkedIn to stay updated with the latest news and insights leading up to Space Tech Bremen 2023. Mark your calendars and join us at our Luxembourguish booth to discover the incredible possibilities that lie ahead in the realm of space activities and lightweight structures. Together, let’s reach for the stars!